SuperChargers

What's required to install a roots style supercharger

How hard is it to install a supercharger? Well it's not really that hard, it's the big picture you have to look at. If it's a roots style supercharger here's how we do it here, but we recommend visiting RCS for your installation.

Before we get into that you need to consider a lot of small concerns and points of interest. Starting with will the current engine foundation allow and support a superchargers potential inceased power, as well as the accessories that are required to operate the engine/vehicle that have to still bolt up and operate correctly. You may have cooling system, throttle linkage, and fuel system modifications. You also have to ask yourself do I have the ability to tune or have tuned the new induction system, keep in mind you are going to increase the current engines power by as much as 200Hp? When tuning if carbureted it will require main jetting changes and some basic adjustments to complete the tune. If EFI, the ECU now has to be recalibrated which will include many of the fuel maps not just the main fuel map. That being said you need a knowledgeable person who knows engines and what is needed and how to tune an ECU correctly. You may want to consider having the engine dyno tuned as well just to make sure you don't hurt the engine due to incorrect installation and tuning. Just remember this, no matter an engines power level supercharged or not never settle for an engine that is not tuned correctly, simple issues like fouling plugs, dirty or black soot. There is absolute on reason your engines spark plugs should contaminated and not burning correctly. A well designed and tuned engine does not need the spark plugs replaced every week due to fouling, regardless of what you have experienced and or heard. Spark plugs shouldn't have to be replaced for a very long time.

The biggie is what gasoline octane is this beast going to run on and not how much boost we're going to make? If it was me I would choose 92-93 octanes depending on where you lived in the country and boost ranges from 7 to 12 lbs. max, hey it is your intention to drive this car everywhere. RCS has successfully built and tuned supercharger engines on 93 octane that make over 1,200HP and 1,100lbs of torque with no more than 12lbs of boost on the street. Yes it can be done, the big picture for something like that is you should use a PROFESSIONAL engine builder to get there, not yourself or some buddies. I don't claim to be a doctor, so why would I operate on myself! Now for smaller engine power levels almost anything can be done fairly easy.

We have some very basic formulas that work very well when installing a new supercharger on an existing engine combination. The goal is not to build boost beyond what is needed or required to create the cylinder pressures that the engine will make when it's at max boost for the octane used. Yes forget about the big boost numbers with low octane fuels. Now if you’re using racing gas with up to 122 octane the sky's the limit until you start heating up the air too much and then you require a intercooler to bring the air density back. As we come back to earth we now can focus on what's real and how to achieve it. Out of all the cars we build, the blower cars get the most attention from the public no matter where you’re at.

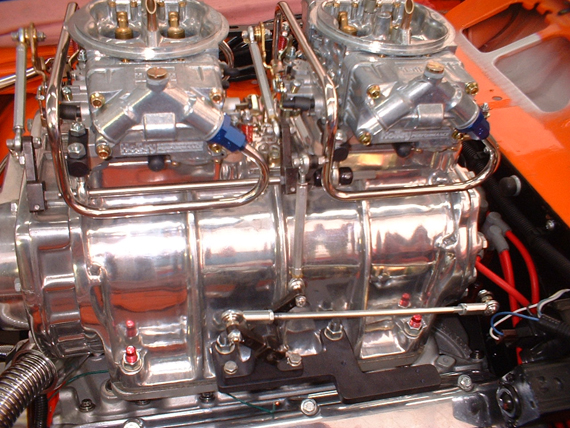

For the intimidation factor most people install a 6 or 8-71 roots type blower, imagine a 14-71, although there are lots of powerful blowers that fit under the hood. If you are using a 71 series blower you’re best sizes for SB are 6-71 and BB the 8-71, the bigger the engine or higher the air flowing rates of the induction is the bigger or better the blower has to be. In short, the better the heads flow, and the bigger the camshaft duration is along with a big exhaust system the bigger or better the blower has to be to create boost.

Let’s talk about boost. If your engine naturally aspirated power is 500Hp and you install an 8-71 with about 7-8lbs of boost your engine will now make about 600hp. Why so little, it takes about 150hp to operate a blower through the power band at 7-8 lbs. of boost, which you don't see and the gain you actually feel is about 100Hp. A gain you will experience at every part of the power band under boost along with the added accelerating HP that comes with it. Now with 10-12lbs of boost you would see around 700hp on the same engine a 200Hp increase. This is the simplest way I can explain the benefits from just adding a supercharger. When we design an engine from the start a lot more is configured in and the power results can be higher for those boost pressures. Just think using a 454 Chevy, your 500Hp engine now makes 700Hp and 700lbs of torque and that's enough power to burn any tire size you can purchase for as long as you want to on the street.

To summarize, the more power your engine makes as a naturally aspirated engine the more power it will make as a supercharged engine when you keep the boost pressures were I stated. Turning up the boost pressure will build more power but at a price in a low Hp naturally aspirated engine. A low HP engines say 300Hp will never see 700Hp just because you installed a blower and cranked up the boost. The operating limits of fuel octane due to the amount of boost required to make 700 will keep it from happening. Keep in mind boost pressure does not mean increase cylinder pressure, meaning the added boost measured in the intake runners does not represent the equal amount added to the cylinder. It is called a fill cycle, with the effects of reversion from the intake cycle there's no way to tell what benefit actually came from the boost in supporting the cylinder pressure, we can only assume.

So what does it take?

The first thing to do is measure cranking cylinder pressure of the current engine correctly. Next we then try to measure or arrive at the intake ports cross sectional area behind the intake valve head. Those two values and the boost pressure we want to run at will tell us whether the 92-93 octane fuel will work. Another variable is whether the heads are steel or aluminum, aluminum heads can tolerate a higher cylinder pressure than a steel head because they dissipate heat faster. What’s important is we have to know what the maximum measured cylinder pressure created is, along with the added boost pressure that enters the cylinder. A safe pressure that will make great power is 210lbs on 92-93 octane fuels, when using ignition timing of around 34-36 total degrees advancement, at a 180 degrees water temperature, with 80 degrees ambient outside air temperature, and when using aluminum cylinder heads.

Let’s say the your measured cranking pressure is 170lbs and add it to our formula. That being you take the calculated cross sectional area of the port behind the intake valve and multiply it times the wanted or needed pounds of boost let's say 12lb. If the cross sectional area of the port is 3.25sqin, which would be less the valve stem diameter area of course, times the boost pressure of 12lbs added to the measured cylinder pressure would be 39lbs plus 170lbs, giving you a total pressure of 209lbs. This is a good starting point that will allow you to proceed with your install.

The focus point is camshaft duration, overlap, valve sizes, static compression ratio, mechanical or hydraulic lifters, cylinder head and intake manifold flow rates, scavenge from the header, actual blower efficiency and pulley ratio controls how much boost pressure you will see. That being said, if you follow my rules you will never hurt your engine for a given fuels octane used.

Depending on the blower pulley needed you may have to change the tooth count to get the boost and cylinder pressures in line for the octane used. If your engine made 14lbs of boost you would have to change the pulley to a larger one to slow down the supercharger or possibly increase the octane rating of the fuel. Caution, when testing at the beginning always use the highest octane you can find so you don't experience denotation in the engine, consult with your supercharger manufacture for pulley ratio's for their blowers to get close.

Just a quick reminder if you were to change the camshaft at the same time you installed the supercharger you still have to assemble that part of the engine and do a measured cranking pressure test. The end result will be the best boost pressure for the octane of fuel used.

With EFI Superchargers life doesn't get much better than this, with monstrous throttle response more than a carbureted equal. Here is a 1000Hp with only 7lbs of boost. With low boost you can drive without the worry of building excessive intake charge heat, which can lead to detonation in a hurry.

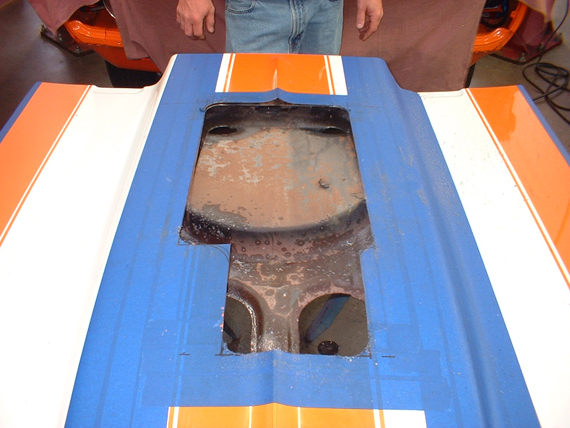

Cutting the hood for your Supercharger

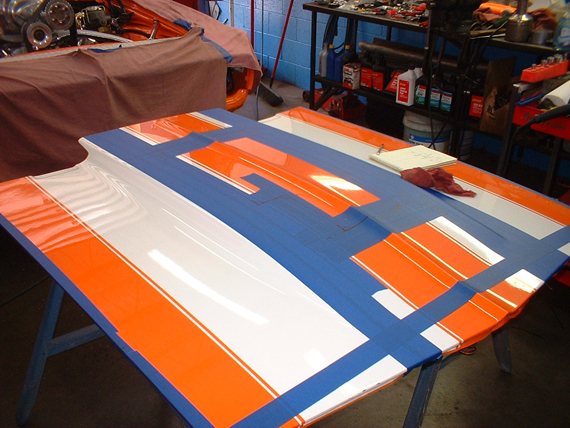

With a car that is already painted it is very possible to cut the hole opening without the need of paint repair.

Preparation is a must and care must be taken as not to scratch the hood by working on it. The blue tape is used for marking and protection, so don't be cheap cover the hoods surface. At this point you have to measure off the fenders and cowl and create a set of measurements that represent the position of the blowers shape related to the its position to the fenders. Take these measurements from the sides, front and rear of the blower. Now you want to transfer those measurements to the hood.

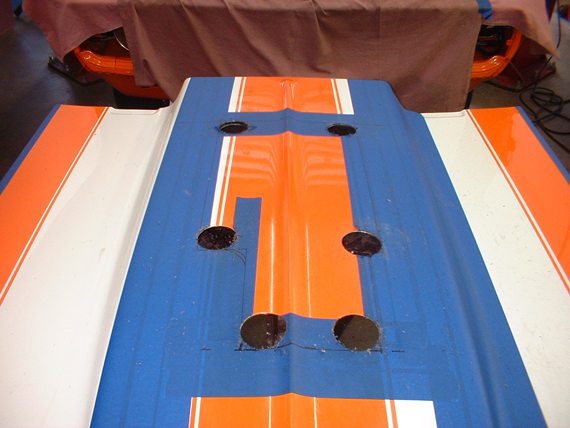

Once you feel you have established the correct opening size it’s time to first cut the curves at which will be the radius of each corner. Once cut use a jigsaw to cut the straight lines to the holes drill. Blend each straight line to the radius with a hand file, be careful not to chip the paint.

Once the top of the hood is cut you have to flip the hood and do the same, but it doesn't have to match the top. The under hood may have a different structure than the top so be careful not to remove too much support for the hood.

After everything is cut and hand filed in the direction of the cut not 90 degrees to the cut. If you file incorrectly you will chip the paint forsure. As for dealing with the bare metal edge we use a simple black Sharpy marker and detail the cut edge.

Only cut what is needed to allow clearance for operation of the linkage and any rotating parts. Also allow for the torque movement of the engine when under a chassis load. The last part is to make sure the hood opens and closes clearing the back of the blower and air filters.